Examination of nontraditional materials for microvertebrate fossil screenwashing

BROOKE K. HAIAR

The Cifelli Lab at the University of Oklahoma, USA, both championed and systematized the use of nested screenboxes for sediment processing in the effort to isolate microvertebrate fossil remains. These particular methods have become the standard of the industry and are capable of winnowing thousands of kilograms of matrix down to quantities that can be reasonably picked through by hand. Other methods for screenwashing using non-traditional materials have been suggested, including nylon mesh bags and paint sieves. In this brief report, the efficacy of both of those newer materials is systemically analyzed and the pros and cons of all three methods are discussed.

The collection and underwater washing (henceforth referred to as screenwashing) of fossil-bearing matrix has long been a practice used in vertebrate paleontology to recover the smaller remains of larger organisms, or the remains of smaller organisms which are often overlooked in quarry work due to their size (Blob and Badgley 2008; Foster and Heckert 2011). Hibbard (1949) championed the idea of deeper investigation of rock matrix for the presence of microvertebrates. He described the screenwashing methods of the time, specifically for unconsolidated Cenozoic-aged material, using both wet and dry methods. McKenna (1962) described the construction of wooden boxes with window screen bottoms, designed for washing matrix in a field setting which was a predecessor to the process described by Cifelli et al. (1996). Rixon (1976) went into great detail on how to separate matrix using stacked sieves and a flowing water source. A sifting machine was created by Ward (1981) which created a more systematic approach to sieving for microvertebrates, but involved a bulky and costly setup. The Cifelli Lab at the University of Oklahoma, USA, pioneered the systematic use of nested screenwashing boxes and the mass processing of large quantities of matrix to recover the often-overlooked smaller fossil components of previously well-sampled vertebrate localities, specifically in consolidated materials. Cifelli et al. (1996) provided the paleontology community with explicit instructions on how to make nested screenwashing boxes that produced two size-classes of matrix, once reduced, as well as the process for an initial wash with water, and secondary washes with kerosene or heavy liquid (e.g., zinc bromide) separation. Wilborn (2009), a Cifelli Lab graduate, furthered this study by systematically analyzing the use of hydrogen peroxide as a secondary wash fluid, which proved to be a safe and more cost-effective way of reducing matrix, especially those matrices composed of swelling clays. Hydrogen peroxide also proved to reduce matrix as efficiently as, or more efficiently than, kerosene in almost all cases.

The traditional screenwashing process is spelled out in detail in Cifelli et al. (1996), but a review is provided below. Two wooden boxes are constructed, one with an 18 mesh (standard window screen, with 1 mm openings) and another with 30 mesh (0.6 mm openings). The coarse mesh and fine mesh boxes are nested inside of each other. Matrix is added to the interior-most box and the set is soaked in water overnight. Large metal or plastic tanks (often on the order of 150 gallon/600 liter, and typically referred to as stock or cattle tanks) are used to hold upwards of 16 screenboxes at a time for soaking. After soaking overnight, the boxes are gently agitated to disaggregate the soaked matrix and allow non-fossiliferous particles to pass through the mesh. The agitation consists of shaking the boxes laterally, while underwater, to move the matrix over the screens. The screenboxes are then separated and laid out to dry, preferably on an elevated surface to permit air flow-through (such as propped against dimensional lumber) and/or on sheet metal to increase the solar reflectivity and speed drying. Since Cifelli et al. (1996) there have been variations in sizes of boxes and coarseness of mesh used in different labs, but the general setup remains the same (Miller 1989; Heckert 2004; Bhat 2017).

One of the more challenging aspects of this traditional screenwashing process is having the space available to wash and dry the screenboxes. Both the washing in the cattle tanks and the drying of the separated boxes have a large footprint. There are often thousands of pounds/kilograms of matrix that need to be screenwashed in order to sufficiently sample a locality. The space needed for a setup to wash any large quantity of matrix is prohibitive at many smaller institutions. Another drawback to this method is that the cost of making the screenboxes themselves can be quite high relative to the budget of some institutions. More recent forays into screenwashing techniques have posited using different materials to contain the matrix to be washed, such as commercially available paint sieves (Avrahami et al. 2015) and kitchen sieves (Araujo et al. 2011). Another often discussed, but not systematically examined, containment method is the use of nylon sacks created from nylon mesh (Grady 1979). This paper discusses smaller-scale alternatives to the traditional screenbox washing technique utilizing 5-gallon/20-liter buckets for soaking, a comparison of paint sieves and nylon mesh bags for screening of material, and the use of a fume hood for drying. The aim here is not to directly compare these methods to traditional screenwashing but to evaluate their overall efficacy in reducing matrix. I also discuss their merits and drawbacks as viable alternatives for bulk processing and microvertebrate recovery at smaller institutions with space or budget constraints, and for use in the field.

Material and methods

Traditional screenwashing.—Traditional screenboxes consist of two boxes nested together. There is a smaller box with a coarse mesh, which fits inside a larger box with a finer mesh. Variations in sizes of boxes exist and are dependent on the user. Cifelli et al. (1996) reports constructing boxes of dimensions 14” × 12.5” (36 cm × 31.8 cm) in size, with a depth of 7.12” (18 cm) for the larger box. The smaller box is 12” × 10.5” (30 cm × 26.7 cm), with a depth of 7.12” (18 cm). A large metal tank, typically referred to as a cattle tank, is suggested as a way to wash up to 16 screenboxes at a time (Cifelli et al. 1996). A tank of this size is difficult to house indoors and is typically placed outside. Access to water and the ability to drain the sediment from the cattle tanks is necessary, and both must be immediately adjacent to the tank location. In the field this can be accomplished with a nearby river or stream, when available, as long as safety precautions are made for sudden changes in discharge rate. A pump system can also be used to fill and empty tanks adjacent to nearby water sources. Screenwashing of this type done in an indoor lab setting requires the space for the cattle tanks, a water source, and a place for periodic disposal of the sediment that settles in the bottom of the cattle tanks. There also needs to be a separate space available for drying the separated screenboxes. To remove the reduced matrix from the nested screenboxes, typically a large piece of fabric is laid out and the boxes are emptied onto it. The boxes are then struck to make sure any material stuck in the mesh is removed. This is repeated for each screen size. Care is needed before using the boxes for a different collection locality as some material can become stuck in the mesh; the mesh needs to be carefully brushed to prevent any accidental contamination.

Paint sieves.—Paint sieves (or paint strainers) are readily available materials from any paint or hardware store. These bags are made of nylon and come in 5-gallon (20-liter) bucket sizes. A quick search at an online store shows them to be about 1 US dollar apiece, so they are cheap and disposable. The standard mesh size of the paint sieves results in one size component of the reduced matrix, with a hole approximately 0.16 mm in diameter (Avrahami et al. 2015), which is equivalent to 100 mesh size. After filling with matrix, the bags can be cinched closed with twine or nylon rope, then submerged in water and soaked overnight. Once soaked, the material needs to be agitated. This is done by lifting the bag in and out of the water for approximately a minute, then breaking up any mud layers on the bottom of the bag by gently pushing against the bottom of the bag by hand, and finally a repeat of lifting in and out of the water for another minute. Reduction is complete when the bag appears to not lose any more appreciable mass. Removal of the material from the paint sieves is much simpler than for screenboxes as there is only one size component to consider. The dried material can simply be poured into a container. Material can become stuck in the mesh, and gentle brushing of the outside of the sieve with fingers can remove most visible material. Since the paint sieves are disposable there is no need to clean them to prevent cross-contamination between localities.

Nylon mesh bags.—Rolls of nylon fabric are available from a variety of netting suppliers online and potentially locally, as well. Most stores have a variety of mesh sizes. For this experiment an attempt was made to replicate the screenbox sizes of 30 and 18 mesh. The 18 mesh results in a hole 1 mm in diameter; the 30 mesh is 0.6 mm. Netting in 1 mm and 0.5 mm sizes was purchased, which resulted in slightly smaller mesh openings than the original 30 of the screenboxes. The 1 mm fabric was cut into 30” (75 cm) diameter circles, and the 30 mesh/0.5 mm was cut into 36” (90 cm) diameter circles. The resultant materials were laid out on top of one another (coarser mesh fabric on top) and a standard amount of weighed matrix was added. Both circles were then cinched closed with nylon rope and soaked overnight. The agitation method was the same as that for the paint sieves with the exception that the inner-most bag was the one with mud buildup that needed to be broken up. The nested nylon bags produced two sizes of material which were kept separate in order to speed picking. Once dried, the bags were untied and the inner bag was lifted out. The inner bag was gently shaken to remove any material from sticking to the bottom of it. One edge of the bag was then released from the gathered nylon and put into the receiving container. The consolidated material was then poured in. The process was repeated for the outer bag. As with the paint sieves, material could become stuck and gentle brushing of the outside of the bag with fingers removed the material.

Both the paint sieves and the nylon mesh bags were soaked in 5-gallon (20-liter) buckets. The space available for this project allowed for nine buckets to be used at a time. The nylon rope used to cinch the bags shut was looped around a wooden brace in order to suspend the bags and prevent contact with sediment at the bottom of the bucket (Fig. 1). After soaking, the bags were agitated gently (described above). The bags were then placed on an elevated dish drying rack in a fume hood for drying. This particular hood was not connected to a ventilation system as venting of the air is not required, only the flow-through circulation to dry the matrix. This allowed the reduced matrix to be dried in no more than 8 hours. For this experiment, the reduced matrix was weighed for both the paint sieves and the nylon bags in order to determine percent mass reduction. The nylon bags resulted in two size fractions of washed concentrate. The end masses of the fine and coarse fractions were weighed separately, added together, then subtracted from the original mass.

Fig. 1. Photograph showing how the screenwashing setup can be arranged in a small space. Each bucket contains the nested nylon bags holding the matrix and cinched shut with a nylon rope. The rope is then looped around a wooden brace to prevent the bags from sitting on the bottom of the bucket. The braces are also useful for pulling the bags in and out of the water for agitation before drying. The set up for screenwashing with paint sieves (not pictured) is the same, including the use of the braces.

Matrix material.—The matrix used for this experiment was from the Morrison Formation, an Upper Jurassic terrestrial deposit. It was collected from the Two Sisters 2 Quarry, a vertebrate locality in northern Wyoming, USA, excavated by the Virginia Museum of Natural History (Martinsville, USA) and the University of Lynchburg (Lynchburg, USA) (Wilborn 2006; Haiar and Porter 2016). This particular quarry is located in the lower part of the formation, approximately 15 m above the contact with the underlying Sundance Formation. The Morrison Formation varies greatly in thickness but composite sections from Wilborn (2008) propose a total thickness of 53–63 m in this region. While no official member names have been assigned to the Morrison Formation in this area, the quarry is located in Unit 1 of Ostrom’s (1970) stratigraphic system, in the Upper Jurassic. The lithology is a sandy siltstone with calcite cement and swelling bentonitic clay. The matrix used for this experiment was collected during the excavation of large dinosaur fossils. Any rock removed during excavation was collected and processed for microvertebrate fossils.

Results

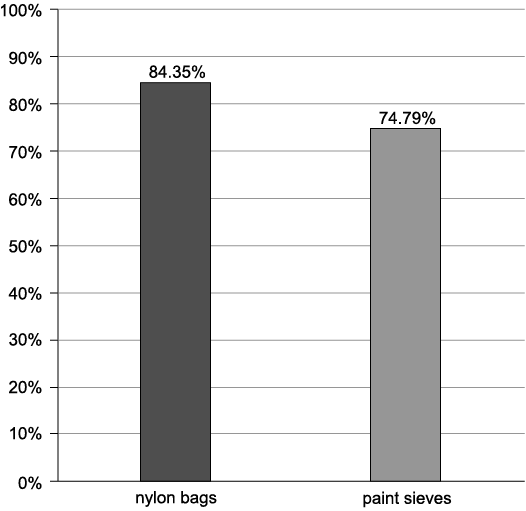

There were 13 799 g of matrix processed over 48 replicate samples using the paint sieve method. The average percent mass reduction for samples processed using paint sieves was 74.79 % (Table 1). The nested nylon mesh bags had an average reduction rate of 84.35 % over 19 replicate samples and a starting total mass of 9991 g (Table 2). Figure 2 illustrates the comparison in reduced matrix between the two methods.

Table 1. Results from screenwashing using paint sieves. Matrix was collected from the Two Sisters 2 Quarry located in the lower part of the Morrison Formation, Upper Jurassic, in northern Wyoming, USA. All measurements are in grams.

|

Original mass |

End mass |

Reduction (%) |

|

298.84 |

69.69 |

76.68 |

|

267.24 |

79.45 |

70.27 |

|

285.94 |

100.22 |

64.95 |

|

262.70 |

85.23 |

67.56 |

|

298.73 |

53.36 |

82.14 |

|

298.68 |

64.06 |

78.55 |

|

296.53 |

55.44 |

81.30 |

|

297.64 |

55.70 |

81.29 |

|

285.20 |

53.52 |

81.23 |

|

294.62 |

61.65 |

79.07 |

|

299.11 |

60.04 |

79.93 |

|

299.64 |

50.64 |

83.10 |

|

300.01 |

58.14 |

80.62 |

|

297.48 |

59.50 |

80.00 |

|

297.29 |

55.99 |

81.17 |

|

299.25 |

56.64 |

81.07 |

|

295.59 |

68.77 |

76.73 |

|

281.29 |

107.38 |

61.83 |

|

243.37 |

189.35 |

22.20 |

|

272.51 |

62.77 |

76.97 |

|

299.69 |

95.08 |

68.27 |

|

249.38 |

71.72 |

71.24 |

|

273.47 |

97.72 |

64.27 |

|

277.59 |

79.74 |

71.27 |

|

245.52 |

96.48 |

60.70 |

|

260.32 |

77.22 |

70.34 |

|

254.50 |

71.14 |

72.05 |

|

280.20 |

78.53 |

71.97 |

|

278.96 |

98.98 |

64.52 |

|

296.27 |

87.33 |

70.52 |

|

288.82 |

83.19 |

71.20 |

|

297.33 |

89.23 |

69.99 |

|

286.64 |

83.97 |

70.71 |

|

294.23 |

81.95 |

72.15 |

|

297.00 |

73.47 |

75.26 |

|

296.02 |

86.58 |

70.75 |

|

296.25 |

62.75 |

78.82 |

|

288.23 |

57.63 |

80.01 |

|

288.94 |

49.89 |

82.73 |

|

294.79 |

48.37 |

83.59 |

|

298.97 |

50.29 |

83.18 |

|

298.55 |

52.54 |

82.40 |

|

299.71 |

42.28 |

85.89 |

|

299.10 |

56.54 |

81.10 |

|

299.45 |

53.27 |

82.21 |

|

297.57 |

53.38 |

82.06 |

|

299.06 |

49.37 |

83.49 |

|

291.26 |

50.76 |

82.57 |

Table 2. Results from screenwashing using nylon mesh bags. Matrix was collected from the Two Sisters 2 Quarry located in the lower part of the Morrison Formation, Upper Jurassic, in northern Wyoming, USA. This method produces two size fractions of washed concentrate. End masses (Fine and Coarse fractions) were added together, then subtracted from the original. All measurements are in grams.

|

Original mass |

Fine |

Coarse mass |

Total mass remaining |

Reduction (%) |

|

269.8 |

3.8 |

27.7 |

31.5 |

88.32 |

|

548.7 |

4.4 |

64.6 |

69.0 |

87.42 |

|

460.0 |

3.6 |

54.3 |

57.9 |

87.41 |

|

635.9 |

7.4 |

121.4 |

128.8 |

79.75 |

|

445.9 |

12.7 |

78.7 |

91.4 |

79.50 |

|

451.0 |

10.9 |

59.8 |

70.7 |

84.32 |

|

487.0 |

10.7 |

72.5 |

83.2 |

82.92 |

|

543.6 |

21.6 |

73.7 |

95.3 |

82.47 |

|

611.2 |

19.5 |

95.2 |

114.7 |

81.23 |

|

613.9 |

10.3 |

80.9 |

91.2 |

85.14 |

|

589.5 |

17.7 |

71.7 |

89.4 |

84.83 |

|

477.0 |

14.3 |

21.5 |

35.8 |

92.49 |

|

398.6 |

9.2 |

37.6 |

46.8 |

88.26 |

|

510.0 |

12.5 |

37.4 |

49.9 |

90.22 |

|

447.4 |

10.6 |

56.4 |

67.0 |

85.02 |

|

572.0 |

7.9 |

46.9 |

54.8 |

90.42 |

|

660.9 |

23.3 |

142.3 |

165.6 |

74.94 |

|

604.9 |

12.2 |

72.6 |

84.8 |

85.98 |

|

664.6 |

26.0 |

160.8 |

186.8 |

71.89 |

Discussion

In order for the proposed screenwashing materials to be considered viable alternatives to nested screenboxes they needed to produce significant reduction in the original matrix. There is a lack of literature that reports percentage of weight reduction from traditional screenwashing using screenboxes. Typically, results between 70–80% of reduction can be expected, depending on lithology (Kyle Davies, personal communication 2022). While this paper is not attempting to compare these methods directly, the results of using the paint sieves and nylon bags are comparable to that of traditional screenboxes, with the nested nylon mesh bags reducing the original matrix by a greater percentage than the paint sieves. This greater reduction of mass means significantly less time is spent picking through the matrix afterwards. The mesh bags also result in two size fractions of washed material, which allows for speedier picking. The paint sieves did not reduce the matrix as much because the mesh size was too fine to allow much non-fossiliferous material to pass through, though the total mass reduction is comparable to traditional methods. If it has been previously demonstrated, or is suspected, that the original matrix contains fossil material smaller than 0.5 mm, the paint sieves could be utilized. However, as an alternative, I would suggest acquiring a third nylon fabric with a tighter weave and screenwashing the matrix through all three nested bags.

Both the nylon bags and paint sieves have the benefit of being lightweight, inexpensive, and highly portable. These materials can be used to field test a locality for the presence of microvertebrates without the need for collecting and bringing vast samples of matrix back to the lab (Eberth et al. 2008; Andrew B. Heckert, personal communication 2021). Once a fossiliferous deposit is identified the use of these materials in the field could drastically reduce the logistical issues related to hauling screenboxes and cattle tanks to a field site. In theory, both the bags and sieves could be filled with matrix and tied to a weight to soak in a river overnight for processing in bulk, if available.

The softer, nylon fabric could possibly be gentler on wet fossil material than the metal screens of a traditional screenbox, though this is an anecdotal observation. On the other hand, there is also the possibility of stretching of the nylon material which might cause undue stress on a specimen resulting in strain or breakage of the fossil. Avrahami et al. (2015) demonstrated that due to the webbed nature of the paint sieves the size of the holes in the material while under pressure and wet were actually smaller than when they were dry. This prevents material washing through that is too large, but if a fossil particle is trapped in the webbing it could be broken.

Using the 5-gallon (20-liter) buckets for soaking matrix, either with nylon bags or paint sieves, drastically reduces the footprint needed for a screenwashing setup. It potentially slows down the rate of washing since one can only use so many buckets at a time, whereas the traditional, larger setup allows for processing in bulk at greater speeds. But if the space is not available, the buckets seem a feasible alternative.

A benefit to traditional screenwashing is the volume of matrix that can be processed at one time. Using 5-gallon (20-liter) buckets means the volume of material that can be washed is determined by the space available for buckets. However, when used for testing localities for viability, soaking the bags in their own individual buckets will prevent cross-contamination and allow multiple sites to be run simultaneously. The drying time of the wet matrix is also going to be higher in the paint sieves and nylon mesh bags than if the boxes were laid out in the sun simply due to the smaller surface area of the condensed matrix exposed to the air in the bags. In the field, I would suggest the bags be opened to allow for more surface area to be exposed to the air and speed drying time. A workaround for a lab setup used in this study was to place the wet samples on an elevated dish drying rack in a surplus fume hood. The hood was placed in the research area but did not need to be connected to the building’s air flow. The samples dried overnight, a speed similar to that of traditional screenboxes, depending on climate. Any fume hood could be used in such a manner to increase the speed of drying.

Fig. 2. Comparison of mass reduction between the nylon mesh bags and the paint sieves. The numbers reported are averages from all samples. The original matrix lithology was a sandy siltstone with calcite cement and swelling bentonitic clay collected from the Morrison Formation, an Upper Jurassic terrestrial deposit. This material was collected from the Two Sisters 2 Quarry, a fossil vertebrate locality in northern Wyoming, USA. Approximately 15 kg of original matrix was processed using the paint sieve method, and approximately 10 kg of original matrix was washed using the nylon bags.

Conclusions

Traditional screenwashing using nested boxes, large containers for soaking, and spread out areas for drying allows for large quantities of matrix to be reduced in a short time. However, there is significant cost associated with the materials needed, as well as a large amount of space needed for both washing and drying of the matrix. Adoption of some of the techniques discussed above, including nylon mesh fabric cut into bags, or the use of paint sieves, could allow those at smaller institutions to process matrix samples for microvertebrates without a significant cost or space investment. The nylon mesh bags appear to be the best at replicating the results achieved with traditional screenwashing, reducing the matrix by 84.35 %, and are highly recommended.

Acknowledgements.—Thanks to Rachel Cooke and Marina Reid (both University of Lynchburg, USA) for help in processing matrix. Suggestions and comments from Brian Davis (University of Louisville, USA), Laura Henry-Stone (University of Lynchburg, USA), Andrew B. Heckert (Appalachian State University, Boone, USA), Haviv Avrahami (North Carolina State University, Raleigh, USA), and Kyle Davies (Oklahoma Museum of Natural History, Norman, USA) were very helpful in creation of the manuscript and are much appreciated. Appreciation is extended to John Foster (Utah Field House of Natural History, Vernal, USA) and an anonymous reviewer for comments and revisions. A special thanks to my festschrift co-editors, Brian Davis and Matt Wedel (Western University of Health Sciences, Pomona, USA). And thanks go to Richard Cifelli (University of Oklahoma, Norman, USA) for inspiration. Funding for this project was made available by the Schewel Student-Faculty Endowed Research Grant.

References

Araújo, R., Natário, C., and Pound, M. 2011. How to mount an inexpensive sieving lab. Journal of Paleontological Techniques 9: 1–8.

Avrahami, H.V., Heckert, A.B., and Martin, L. 2015. Comparison of nested sieves, traditional screen boxes, and paint sieves for the recovery of microvertebrate fossils. Journal of Vertebrate Paleontology 35 (Supplement): 81–82.

Bhat, M. 2017. Techniques for systematic collection and processing of vertebrate microfossils from their host mudrocks: a case study from the Upper Triassic Tiki Formation of India. Journal Geological Society of India 89: 369–374. Crossref

Blob, R. and Badgley, C. 2008. Numerical Methods for Bonebed Analysis. In: R. Rogers, D. Eberth, and A. Fiorillo (eds.), Bonebeds: Genesis, Analysis, and Paleobiological Significance, 333–396. University of Chicago Press, Chicago. Crossref

Cifelli, R.L., Madsen, S.K., and Larson, E.M. 1996. Screenwashing and associated techniques for the recovery of microvertebrate fossils. In: R.L. Cifelli (ed.), Techniques for recovery and preparation of microvertebrate fossils. Oklahoma Geological Survey Special Publication 94-4: 1–24.

Eberth, D., Rogers, R., and Fiorillo, A. 2008. A practical approach to the study of bonebeds. In: R. Rogers, D.Eberth, and A. Fiorillo (eds.), Bonebeds: Genesis, Analysis, and Paleobiological Significance, 265–331. University of Chicago Press, Chicago. Crossref

Foster, J. and Heckert, A.B. 2011. Ichthyoliths and other microvertebrate remains from the Morrison Formation (Upper Jurassic) of northeastern Wyoming: A screen-washed sample indicates a significant aquatic component to the fauna. Palaeogeography, Palaeoclimatology, Palaeoecology 305: 264–279. Crossref

Grady, F.V.H. 1979. Some new approaches to microvertebrate collecting and processing. Geological Curators Group Newsletter 2: 439–442.

Haiar, B. and Porter, K. 2016. Overall body size as an indicator of ontogenetic stage in sauropod dinosaurs. Journal of Vertebrate Paleontology 36 (Supplement): 148.

Heckert, A.B. 2004. Late Triassic microvertebrates from the lower Chinle Group (Otischalkian–Adamanian: Carnian), southwestern USA. New Mexico Museum of Natural History and Science Bulletin 27:1–170.

Hibbard, C. 1949. Techniques of collecting microvertebrate fossils. University of Michigan Contributions from the Museum of Paleontology 8: 7–19.

McKenna, M. 1962. Collecting small fossils by washing and screening. Curator 5: 221–235. Crossref

Miller, B. 1989. Screen-washing unconsolidated sediments for small macrofossils. In: R.M. Feldman, R.E. Chapman, and J.T. Hannibal (eds.), Paleotechniques. The Paleontological Society Special Publications 4: 260–263. Crossref

Ostrom, J. 1970. Stratigraphy and paleontology of the Cloverly Formation (Lower Cretaceous) of the Bighorn Basin Area, Wyoming and Montana. Bulletin of the Peabody Museum of Natural History 35: 1–234.

Rixon, A. 1976. Fossil Animal Remains: Their Preparation and Conservation. 304 pp. University of London, London.

Ward, D. 1981. A simple machine for bulk processing of clays and silts. Tertiary Research 3: 121–124.

Wilborn, B. 2006. Microvertebrate assemblage from a Dinosaur Quarry in the lower Morrison Formation, Bighorn Basin, Wyoming. Journal of Vertebrate Paleontology 26 (Supplement): 138–139.

Wilborn, B. 2008. Paleoecology and Stratigraphy of the Morrison and Cloverly Formations, Bighorn Basin, Wyoming. 277 pp. Unpublished Ph.D. Dissertation, University of Oklahoma, Norman.

Wilborn, B. 2009. The use of hydrogen peroxide (H2O2) in secondary processing of matrix for microvertebrate recovery. Journal of Vertebrate Paleontology 29 (3): 976–978. Crossref

Brooke K. Haiar [haiar@lynchburg.edu], University of Lynchburg, 1501 Lakeside Dr., Lynchburg, VA 24501, USA.

Received 12 October 2021, accepted 7 February 2022, available online 30 March 2022.

Copyright © 2022 B. Haiar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (for details please see http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Acta Palaeontol. Pol. 67 (1): 21–25, 2022

https://doi.org/10.4202/app.00952.2021